Why HBC steel?

HBC Steel Guaranteed Machining Ltd. began serving the manufacturing community in the European Union in the year 2009. Since then, the company has grown from a small one-machine workshop with a couple of people into a multi machine-center machining company with dozens of employees. These days, HBC steel...

Dozens of employees

Certification ISO 9001:2016 and 14001:2016

3.000 m2 site

Motivated, highly-trained experts committed to their work

Serving the aerospace, automobile and petrochemical industries

Manufacturing standard as well as challenging parts (those that others reject as "too difficult"), individually or in small to medium quantity batches

HBC steel: Ready for take-off and landing

The first Makino MAG1 in Central Europe has been installed at HBC Steel Guaranteed Machining, a young but dynamically expanding company located in the Czech city of Olomouc.

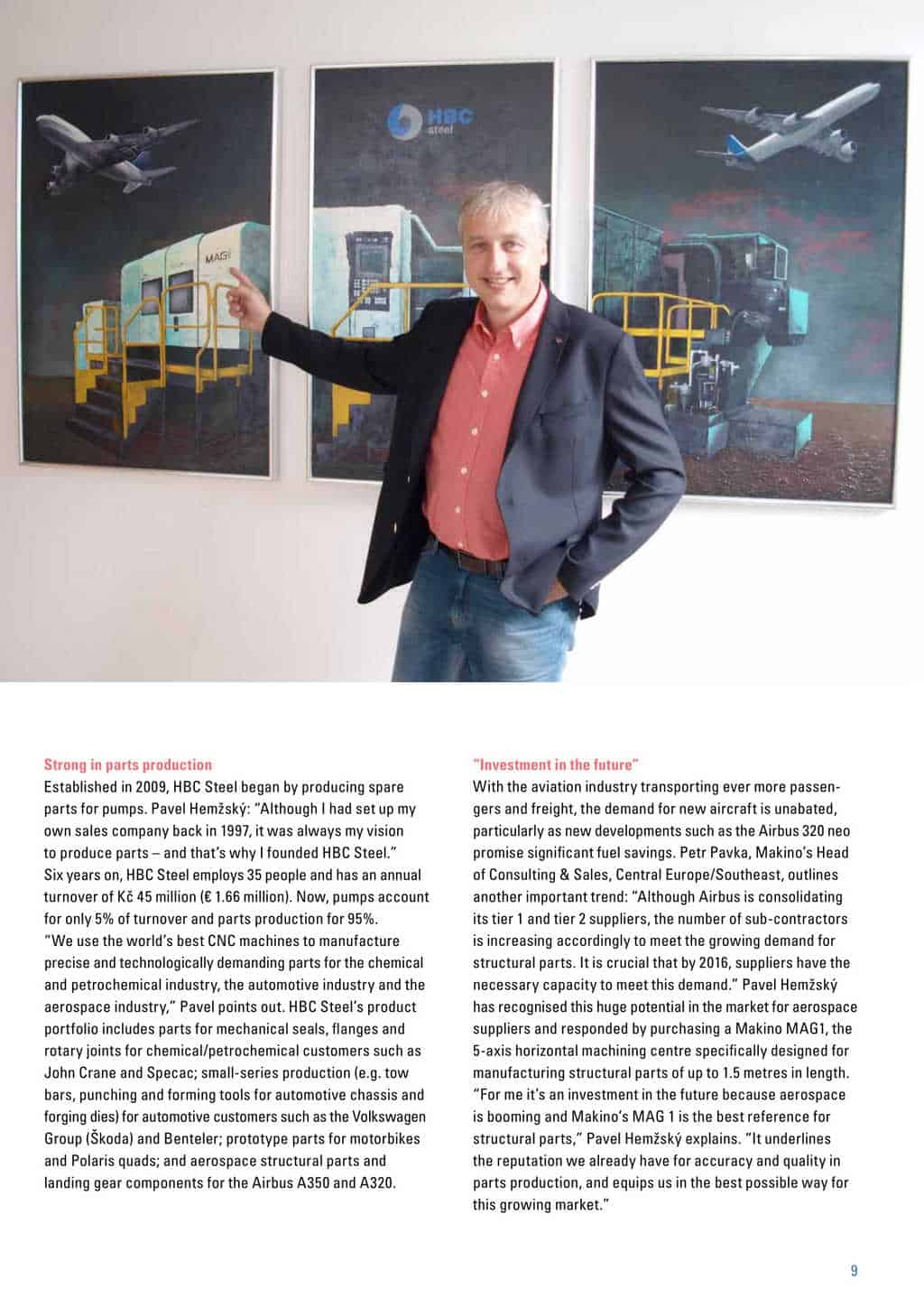

In only six years HBC Steel´s visionary owner, Pavel Hemžský, has built up a thriving job-order parts production business.

Recently, he invested in a MAG1 to equip his company for manufacturing large aerospace parts.

Strong in parts production

Established in 2009, HBC steel began by producing spare parts for pumps. Pavel Hemžský: “Although I had set up my own sales company back in 1997, it was always my vision to produce parts – and that’s why I founded HBC steel.”

Six years on, HBC steel employs 35 people and has an annual turnover of Kč 45 million (€ 1.66 million). Now, pumps account for only 5% of turnover and parts production for 95%.

“We use the world’s best CNC machines to manufacture precise and technologically demanding parts for the chemical and petrochemical industry, the automotive industry and the aerospace industry,” Pavel points out.

HBC steel’s product portfolio includes parts for mechanical seals, flanges and rotary joints for chemical/petrochemical customers such as John Crane and Specac; small-series production (e.g. tow bars, punching and forming tools for automotive chassis and forging dies) for automotive customers such as the Volkswagen Group (Škoda) and Benteler; prototype parts for motorbikes and Polaris quads; and aerospace structural parts and landing gear components for the Airbus A350 and A320.

Investment in the future

With the aviation industry transporting ever more passengers and freight, the demand for new aircraft is unabated, particularly as new developments such as the Airbus 320 neo promise significant fuel savings. Petr Pavka, Makino’s Head of Consulting & sales, Central Europe/southeast, outlines another important trend: “Although Airbus is consolidating its tier 1 and tier 2 suppliers, the number of sub-contractors is increasing accordingly to meet the growing demand for structural parts.

It is crucial that suppliers have the necessary capacity to meet this demand.” Pavel Hemžský has recognised this huge potential in the market for aerospace suppliers and responded by purchasing a Makino MAG1, the 5-axis horizontal machining centre specifically designed for manufacturing structural parts of up to 1.5 metres in length.

“For me it’s an investment in the future because aerospace is booming and Makino’s MAG 1 is the best reference for structural parts,” Pavel Hemžský explains. “It underlines the reputation we already have for accuracy and quality in parts production, and equips us in the best possible way for this growing market.”

Makino’s networking role

“Aerospace is like the automotive industry,” Petr Pavka points out. “It’s all about trusting your suppliers. The key factor is to build up trusting relationships, and our job at Makino is networking – smoothing the way to trusting relationships by bringing quality companies together.”

In the case of HBC steel, Makino was instrumental in establishing a fruitful relationship between HBC steel and the largest aerospace manufacturer in the Czech Republic. One outcome was the purchase of the MAG1 with a 33,000 rpm, 120 kW spindle. The machine was delivered to HBC steel in January 2015 and “installation went very well”, as Pavel Hemžský confirms. But this machine was not the only significant investment Pavel has made in his company’s aerospace future.

Paving the way

For the first five years after HBC steel was established, the company was housed in a small 300 m2 building. But its rapid expansion necessitated a move – not least to accommodate the MAG1 and meet the requirements placed on aerospace suppliers. “In October 2014 we moved to new premises with 3,000 m2 of space for production and 200 m2 for offices,” Pavel Hemžský explains.

“We need approved premises, facilities and equipment to get a clean audit from aerospace tier 1 and tier 2 suppliers. Those conditions are now met, and with the MAG 1 on board we’re ready for take-off !”

The first MAG 1 to be installed in Central Europe means HBC steel is perfectly placed to meet the growing demand for aerospace parts.

This article appeared in the Precisely! Makino Europe´s Customer Magazine.