AS9100D certified

Reliable & guaranteed machining: Aerospace, petrochemical, oil & gas and general engineering

If you are looking for an AS9100D certified machining company that will help you out with your machining, the specialists at HBC steel have shown they can deliver: Already making parts for suppliers of Airbus, Bombardier and Aero aeroplanes. Delivering machined units to suppliers of Volkswagen, Benteler, Polaris and many others.

Our focus at HBC Steel Guaranteed Machining is simple: Deliver the part you ask us to make at the time you need it, in the quality you asked for and at a price that you will be happy with.

Pavel Hemžský,CEO

Some of the parts we have manufactured

If you are looking for precise CNC turning and milling of even the most difficult pieces, HBC steel operators have experience with them all. In addtion, we will (ourselves or with our partners) perform non-destructive tests, heating treatment of your parts, marking of your units with any markings you require, treat the surface the way you want… give us the task and we will always say: „Sure, we will get it done.“ Have others told you „Sorry, it´s too difficult“? You won´t hear that from HBC…

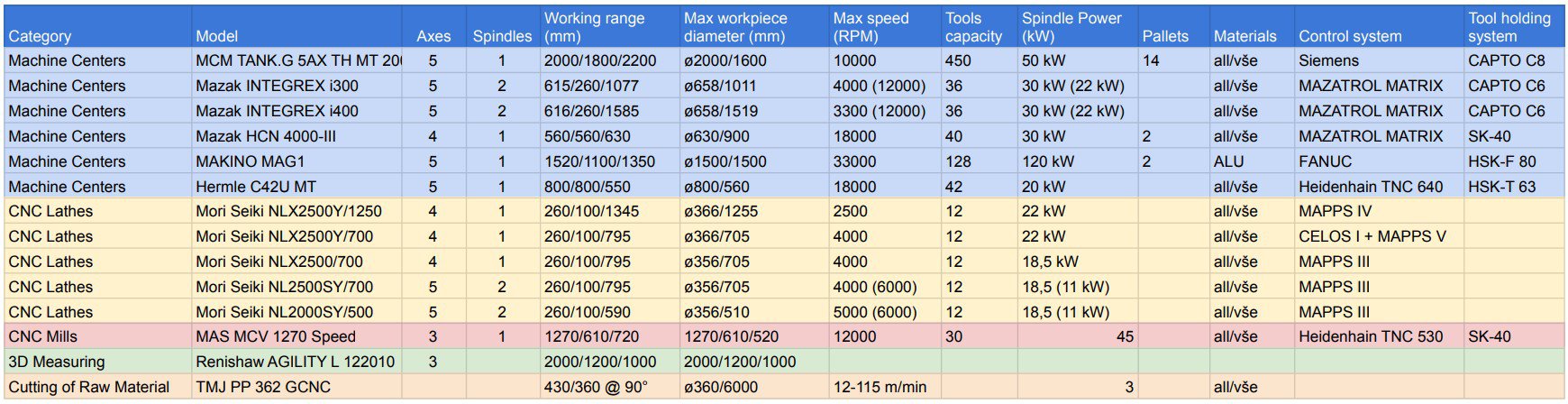

HBC steel can machine workpieces up to 2000 x 2000 mm on advanced 5-axis centres

Using our MCM, Makino MAG1, Mori Seiki, Hermle and Mazak machining centres, we can guarantee rapid precision-contouring capability while maximizing the percentage of in the cut spindle time. The MAG1 centre is ideally suited for high-productivity machining of aluminum monolithic aerospace parts under 1500mm, MCM up to 2000 mm. And in combination with the other smaller centres, we can machine just about any workpiece…

MCM: TANK.G 5AX TH MT 2000: 5 axis machining up to 2000 mm

MAKINO: MAG1: 5 axis machining up To 1500 mm

MAZAK

MORI SEIKI

Professional measuring and testing

At HBC Steel, we are committed to innovation and state-of-the-art technology in precision machining. That’s why we are proud to announce the addition of the Renishaw AGILITY L 122010 to our equipment lineup—a modern coordinate measuring machine (CMM) featuring 5-axis technology.

9 reasons why manufacturers ask HBC steel to do their precise & guaranteed machining…

1. Machined products from HBC steel are used by quality-demanding companies like Airbus, Bombardier, Aero Vodochody, Volkswagen, Benteler

Polaris, John Crane and others

2. HBC can machine workpieces up to 2000 x 2000 mm on advanced 5-axis centres

Using our MCM, Makino MAG1, Mori Seiki, Hermle and Mazak machining centres, we can guarantee rapid precision-contouring capability while maximizing the percentage of in the cut spindle time.

3. HBC is not afraid of challenging parts

If you are looking for precise CNC turning and milling of even the most difficult pieces, HBC steel operators have experience with them all. In addition, we will (ourselves or with our partners) perform non-destructive tests, heating treatment of your parts, marking of your units with any markings you require, treat the surface the way you want… give us the task and we will always say: „Sure, we will get it done.“

4. We can machine just about any material

Do you have special material requirements? No problem. We have worked with and produced parts from steel, stainless steel, cast iron, titanium metal, aluminium alloys, plastics and other unique materials (Hastelloy, Monel, etc.)

5. Problem-free & fast logistics in the European Union

Since we are based in the European Union (Czech Republic), all transportation and administrative steps are easy & simple:

We work will all the major (and minor) logistics companies (DHL, TNT, DB Schenker, UPS etc.). Can prepare your parts for Just in time delivery. And can also store them for you in our own warehouse if necessary.

And since we have experience with the paperwork and customs requirements for non-EU countries too, we can deliver the finished product to anywhere you wish.

6. Machining with the appropriate certificates for European Union (and the world)

We supply parts for various aerospace and car manufacturers and our production is certified according to the standards ISO 9001: 2016 and ISO 14001:2016. And since we supply to the aerospace industry, we fulfill the requirements for an aeroplane parts supplier too.

7. We are accustomed to getting only the drawings and arranging everything else

All you have to do is to send ut the drawings or 3D model. We will then create the strategy of machining, devise a system of fixation, create the appropriate tools and programme the CNC centre ourselves from start to finish.

And to save you money, for each workpiece, we are looking for a way to fixate it, programme the machining and make it to get the result fast, but with minimal waste or risk of defects. Many times, we’ve recommended our clients a different and new production path to save them money.

8. You will get the product appropriately packed and delivered… on time

If necessary, we will deliver your parts in bulk boxes. Or carefully individually packaged. Or in any other way you desire. To transport it a few hundred kilometers to your logistics or manufacturing plant. Or even to the other side of the world. (We have sent products even to Australia.)

9. You can start with an individual piece or a small batch and order more only if satisfied

Call us or write. Describe what you need to have made. What documentation you have. And we will come up with a way to make the part for you… fulfilling all the requirements you set.

HBC steel: Precise machining resulting from experience

If you require precise CNC turning and milling, even for the most complex components, HBC Steel has the expertise to deliver

AS9100D

Ensuring high-quality management standards in manufacturing.

14001:2016

Compliance with environmental management systems.

Professional workmanship

Our team has decades of experience in high-precision machining for aerospace, petrochemical, oil & gas, and industrial applications.

Quality control

Our rigorous quality control ensures that every component meets exact specifications. We don’t compromise on precision.

FULL LOgistics

From EU-wide shipping to global exports, we manage logistics seamlessly, ensuring fast, reliable delivery.

Start here

Let’s discuss your machining needs: info@hbcsteel.cz | +420 585 223 465

Precision components by HBC steel power world-class machines...

HBC Steel’s expertise extends beyond machining—we contribute to some of the most advanced engineering projects in the world. Our precisely crafted components are found in commercial and military aircraft, high-performance quad bikes, oil & gas appplications, industrial machinery, and more. From the skies to the roads, our parts ensure reliability and durability where it matters most.

Why manufacturers ask HBC steel to do their precise & guaranteed machining...

Následující projekty byly realizovány s podporou Evropské unie: